Date of publication :

August 2014

Updated on April 2016

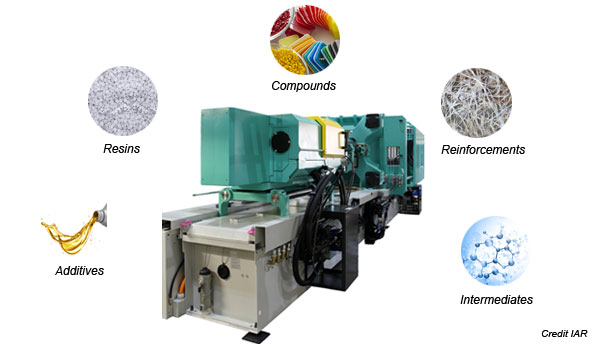

In the framework of a sustainable development, bio-based products are on the rise! In 2010 the European market volume for bio-based products represented € 28 billion, this amount would reach € 57 billion in 2020 (source: European Commision, 2013).

A product is qualified as bio-based when its origin - partial or total - is vegetable (eg crops, wood, algae) or animal (eg fats). Distinguished by their origin, these products now cover a wide range of applications.

This report, focused on products of plant origin, shows examples of applications suitable for the plastic industry. These products feature following advantages:

- new properties (physical and chemical characteristics, end of life, etc.),

- to vary the supply,

- to reduce environmental footprint.

A wide range of polymers |

||||||||||

|

A study made by European Bioplastics and the Institute for Bioplastics and Biocomposites (IfBB, University of Hannover) estimates the worldwide market of bioplastics* in 2011 to 1.2 million tonnes. Market data from this study forecasts production capacities will multiply by 2017 – to more than 6 million tonnes. * The term "bioplastic" groups bio-based and/or biodegradable plastics.

Bio-based polymers include thermoplastic and thermoset resins:

In 2017, the previously mentionned study classes bio-based thermoplastic polymers in the following order in terms of production volume: 1# bio-PET, 2# PLA, 3# bio-PE, 4# Biodegradable polyesters, 5# Mix starch, 6# PHA & PA.

Bio-based resins can be used in a wide variety of applications, with more or less demanding specifications: from automotive to packaging, from electronics to consumer goods, etc. The study indicates that in 2012, the packaging industry was the most important user of thermoplastic bioplastics, followed by the automotive and electronic sectors.

Examples of products |

||||||||||

|

|

||||||||||

|

PLA |

Unsatured polyester |

PET |

Polyamide |

|||||||

|

|

Each resins can have one or more ends of life:

Examples of products |

||||||||||

|

|

|||||||||||

|

Possible ends of life: compost, soil or water degradation , methanation |

Possible ends of life: biodegradable and compostable according to EN 13432, recyclable |

||||||||||

|

Discover all offered resins registered on the website Agrobiobase. |

|||||||||||

Chemical intermediates for resins and additives |

||||||||||

|

Among bio-based intermediates, there are chemicals used for the synthesis of resins and those used for the production of additives. For example, epichlorohydrin is used for synthesis of epoxy resins, 1,3-propanediol for the manufacture of PTT (polytrimethylene terephthalate), succinic acid to obtain PBS (polybutylene succinate). Several plant-based intermediates exist today for the production of polyurethanes: polyols, isocyanates, succinic acid, isosorbide. Bio-based chemicals are also available for the synthesis of additives for plastic implementation (eg plasticizer).

Examples of products |

||||||||||

|

|

||||||||||

|

Epichlorohydrin |

Isosorbide |

Intermediate to produce light stabilizers |

||||||||

|

|

||||||||||

Plant-based additives for plastic processes |

||||||||||

|

Suppliers offer bio-based processing aids to implement plastics (petro-based or bio-based), like plasticizers, release agents, corrosion inhibitors, etc.

Examples of products |

||||||||||

|

|

|

|||||||||

| Waxes |

Plasticizers |

|||||||||

|

|

||||||||||

Reinforcement made from natural fibres |

||||||||||

|

Natural fibres (flax, hemp, wood, kenaf, sisal, coconut, jute, etc.) are integrated in some plastics, to provide them mechanical properties and improve their environmental profiles. Automotive industry already uses this type of reinforcements to lighten vehicule parts.

Examples of products |

||||||||||

|

|

||||||||||

|

Reinforcement for thermoplastics |

Cutted natural fibres |

|||||||||

|

|

||||||||||

Compounds made with bio-based products |

||||||||||

|

Among compounds made from previously mentionned raw materials, either only bio-based matrix (resin) are used, or only bio-based reinforcement (fibre), or both.

Examples of products |

||||||||||

|

|

||||||||||

|

Composite reinforced with natural fibres |

Composite wood / biobased polyesters |

|||||||||

|

|

||||||||||

Bio-based and product origin

A bio-based product does not mean it is 100% derived from biomass. It is common to have various origins in a product (fossil, mineral, plant or animal) to take advantage of each constituent.

The choice of material is indeed based on three main motivations for industrials:

- Optimize costs and vary its supply to always be competitive if market fluctuations,

- Get new features and properties,

- Reduce environmental footprint.

Incorporation rate

The rate of incorporation of bio-based materials depends on the family of products and existing technologies. Certain classes of products are actually more advanced in terms of incorporation of bio-based materials. For this reason it is important to integrate this parameter in the analysis of bio-based content.

How bio-based content is measured?

Today there is no legal framework to define accurately a bio-based product, whether in terms of definition or in terms of bio-based content measurement.

One of the most widely used methods is based on the calculation by percentage weight (or volume) of the various components of a product to assess its bio-based content.

To communicate with their customers, manufacturers also use independent analyzes (via a third party), on the content of bio-based carbon and the content of other elements from biomass (oxygen, nitrogen, ...) of their products.

Normative framework

At European level, several standards, technical specifications and reports have recently been published on bio-based products. These documents cover the vocabulary (EN 16575: 2014), the life-cycle assessment (EN 16760: 2015), the bio-based content (EN 16785-1: 2015), the sustainability criteria (EN 16751: 2016), the bio-based carbon content (CEN / TS 16640: 2014), the methods for determining the bio-based content (CEN / TR 16721: 2014), and the requirements and methods related to bio-based solvents (CEN / TS 16766: 2015).

All these documents were made in the framework of the technical commitee CEN/TC 411 Bio-based products.

Not to be confused

It is important to note that the origin of a product does not predict anything in its environmental impact: renewability, toxicity, end of life, greenhouse gas emissions, energy consumption during the manufacturing etc..

The life cycle analysis here is a tool for industry to assess the potential environmental impacts and to judge at best the product, from its design to its end of life.

It is also important to distinguish the manufacturing process and the origin. For example, a product cannot be considered as bio-based if it is obtained by fermentation of a fossil substrate by a microorganism.

Written by J. BAUSSET, A.-S. HERVIEUX, M. LOYAUX; IAR cluster

Reference: Bio-economy and sustainability: a potential contribution to the Bio-economy Observatory, page 39, European Commission, 2013

Photos/graphics credits: ShutterStock (report's logo, pictures 15 and 18), IAR (illustration 1), Natureplast (2), CCP Composites (3), FKuR Kunststoff GmbH (4), Arkema (5), Kaneka Belgium NV (6), Biotec GmbH (7), Nadezda Razvodovska - Fotolia (8), Solvay (9), Roquette (10), Arkema (11), Okea-Fotolia.com (12), Cargill (13), Novance / Oleon (14), Sonae Indùstria (16), Procotex Corporation SA (17), AFT Plasturgie (19), FuturaMat (20)